The causes & dangers of over-production

n the relentless pursuit of progress and profit, modern society has entangled itself into a precarious web of overproduction. Every year, half a million tons of microfibers end up in the ocean. Additionally, annual textile waste is projected to surge to a staggering 148 million tons by 2030. Such figures ignite urgent alarm for our planet's environmental future.

For many decades, the mantra ‘more production, more profit’ has echoed in the meeting rooms of businesses and manufacturing sectors, propelling economic growth and fueling consumer demand. Yet, there lurks a danger that poses a serious threat to the environment and the fundamental pillars of the economy and social systems.

A phenomenon deeply entrenched in the modern industrial world, ‘overproduction’ is the excessive production of goods or services. When the produce exceeds the market’s demand, it results in wasted resources, environmental degradation, economic instability, and more! Meanwhile, consumers are flooded with an endless array of products, many of which serve little purpose other than to contribute to the conspicuous cycle of overproduction and overconsumption.

In the wake of these challenges, there is an urgent need for awareness among businesses and consumers alike. In this blog post, Qalara delves into the essence of overproduction, explores the causes of its existence, examines its effects, and proposes long-term solutions to address this looming issue.

Understanding overproduction

In instances where demand outweighs supply, businesses face the risk of losing potential customers and profits to their competitors. As a precautionary measure, they often opt to be on the safe side and speed up production to meet or exceed anticipated demand. However, in fiercely competitive markets where businesses solely prioritize profit maximization, overproduction becomes inevitable.

Karl Marx, a pivotal figure in economic theory, best known for his work ‘The Communist Manifesto’, discussed the perils of overproduction arguing that overproduction is an inevitable outcome when businesses drive for profits and market dominance, with the potential of causing economic crises and labor abuse.

In contemporary times, Karl Marx’s theory of overproduction remains strikingly relevant, particularly observable within the fast-fashion industry. It is important to note that the fast-fashion industry is not the only one producing tonnes of waste. Indeed, they are generating waste at an unprecedented rate, however, luxury brands also deserve critique.

⬝ Causes

1. ‘What if’ inventory & inaccurate forecasting

Despite advancements in data analytics and market research, accurately predicting consumer demand remains a challenge. Moreover, with globalization opening up markets worldwide, many manufacturers aim to cater to a global audience. This often results in companies overestimating demand, leading to imbalances in supply, and contributing to overproduction.

Case study – The Great Depression in the United States: In the 1920s, there was a significant boom in the American economy, fueled by factors like technological advancements, increased consumer spending, and easy credit. This led to a period of prosperity and rapid industrialization. Farmers, swayed by high demand and high prices during World War I, expanded their operations and invested heavily in new equipment and land. However, as the 1920s progressed, the demand for agricultural products began to decline due to a variety of factors, including overproduction, changes in consumer preferences, and changes in trade policies.

Despite signs of oversupply and declining prices, many farmers continued to produce at high levels, driven by the belief that the demand would eventually rebound. However, this optimistic outlook was not supported by accurate market analysis. As a result, agricultural markets became flooded with surplus goods, leading to a collapse in prices. The failure of accurate forecasting and the subsequent overproduction exacerbated the economic downturn, contributing to the onset of the Great Depression. Farmers faced financial ruin as prices plummeted, leading to widespread farm foreclosures and rural poverty.

2. Cost effectiveness

Producing goods in large quantities seems more economical initially, as it reduces per-unit costs. However, this approach often backfires as the demand may not always meet expectations. In such cases, companies find themselves with excess inventory that becomes a financial burden rather than a cost-saving measure, and ultimately this inventory is discarded in the landfills.

3. Seasonal changes and fleeting trends

The fashion industry is notorious for overproduction due to seasonal changes and fast trends. Brands like H&M and Zara have accelerated the pace of their collections, with H&M boasting 12-16 collections annually and Zara releasing new collections every few weeks. This constant flux makes it difficult for other companies to accurately gauge demand, leading to overproduction of items that are likely to end up being unsold. Consequently, brands are forced to resort to discounting and big sales to clear excess inventory, diminishing the perceived value of their products, all the while eroding profit margins in the process and still, having piles of these products to throw away.

4. Competition

Businesses often engage in aggressive production strategies, which leads to over-investment in production capacity. This over-investment, coupled with the desire to undercut competitors through lower prices, results in an excess of goods relative to demand, eventually leading to overproduction.

5. Busting the myth: ‘More production, more profit’

Many businesses believe that increasing production automatically leads to higher profits. However, this belief overlooks the complexities of supply and demand dynamics and can lead to detrimental consequences. Ramping up production and overlooking consumer demand results in excessive inventory. Moreover, as production scales up, companies encounter diminishing returns, where additional units produced yield lower profits due to factors like increased costs or market saturation, diminished profit margins, and financial risks. It is also important to note that chasing higher production volumes can compromise product quality, strain resources, and impose undue stress on workers, which in turn is likely to harm the brand’s reputation.

⬝ Businesses’ motivation for overproduction

Overproduction in the context of brands often stems from a combination of psychological factors and market pressures.

Brands keenly observe and react to trends, and produce items that align with current consumer preferences. However, the transient nature of trends means brands must constantly churn out new collections or products. They believe that if they fail to produce enough of a popular product or the new trend in the market, they might lose customers to competitor businesses, and lose relevance in the eyes of the customers.

In addition, just like how consumers over-buy products for fear of missing out (FOMO), similarly, brands also fear missing out on potential sales opportunities. This fear is amplified by social media, where trends spread rapidly, creating a sense of urgency among businesses to produce more to meet demand. Furthermore, bulk production also enables brands to negotiate favorable deals with suppliers and distributors, enhancing cost efficiency.

Industries like fashion and consumer goods face relentless pressure to maintain relevance and competitiveness, all the while aiming to make maximum profit. Consequently, brands overproduce as they prioritize short-term gains and market visibility over long-term sustainability.

Also read: Rising issues of greenwashing

Effects of overproduction

The consequences of overproduction ripples through societies, economies, and ecosystems alike, and manifests in a myriad of ways that challenge the foundations of our world. As we navigate through this complex issue, understanding its multifaceted impacts becomes imperative.

⬝ Economic impact

1. Price erosion:

When there’s excess supply, prices inevitably plummet. This downward spiral, fueled by the surplus of goods flooding the market, slashes profit margins for producers as consumers grow accustomed to seeking out bargain deals, and the product’s value declines. Moreover, as the market reaches saturation, intensified competition among sellers escalates this trend, leading to further price erosion as businesses strive to capture the attention of a limited pool of consumers.

2. Resource drain and waste:

In addition to flooding the market with surplus goods, overproduction also drains resources. The heaps of unsold inventory in the warehouses signifies a waste of capital on raw materials, labor, and energy expended in vain. The cycle perpetuates as excess production generates excess waste, further straining both economic and ecological systems.

3. Employment fallout:

Behind every product lies a network of labor, from factory workers to supply chain managers. However, this intricate web of employment is threatened in the wake of overproduction. As demand goes down because of excessive supply, businesses are forced to scale back production, often resulting in layoffs and reduced working hours. As individuals find themselves unemployed, their purchasing power diminishes, creating a cascading effect on consumption. This further intensifies the problem of excessive inventory and also creates an economic crisis.

⬝ Environmental consequences

Posing a grave threat to the health and stability of our planet, the environmental consequences of overproduction are manifold, severe, and even irreversible.

1. Pollution:

Overproduction fuels a relentless cycle of resource extraction, leading to the depletion of natural resources at unsustainable rates. Whether it is mining for minerals, cutting down forests for wood, or drilling for oil, the extraction process takes a heavy toll on ecosystems. Moreover, the manufacturing and transportation of goods result in the release of pollutants into the air, water, and soil. From toxic chemicals used in production to greenhouse gases emitted by trucks carrying textile waste to landfills, the byproducts of overproduction endanger both human and ecological health.

2. Climate change:

Perhaps the most pressing environmental issue of our time, climate change is inextricably linked to overproduction. The production and consumption of goods require vast amounts of natural resources. As a result, greenhouse gas emissions skyrocket and trap heat in the atmosphere, ultimately destabilizing the climate. An estimate suggests that textile production alone emits 1.2 billion tonnes of greenhouse gases into the atmosphere every year. If things continue to go at this pace, the ramifications of climate change will be catastrophic, threatening the very existence of countless species, including our own.

3. Biodiversity loss:

A significant portion of the fashion industry’s impact on biodiversity stems from habitat change caused by agricultural practices for cultivating natural fibers. Moreover, additional land is required for factory construction and transportation, encroaching on areas that could otherwise be conserved to protect biodiversity. The degradation of biodiversity leads to cascading effects throughout ecosystems, upon which human society ultimately depends.

Also read: What makes Qalara a planet-friendly choice

⬝ Social implications

In current times, the constant churn of consumer goods, the ceaseless drive for economic growth, and the insatiable demand cast a long shadow over society.

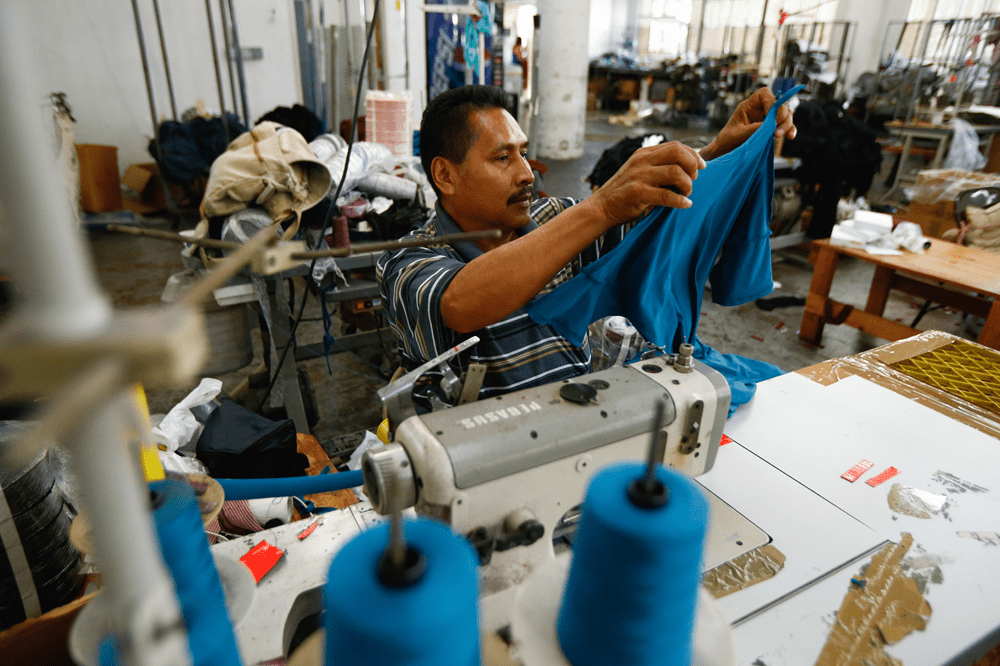

1. Labor exploitation:

The ever-increasing demand for cheap goods fuels a cycle of exploitation, perpetuated by a never-ending pursuit of profit at any cost. Factories in developing countries churn out goods at an alarming rate, often at the expense of workers’ rights and dignity.

A research conducted by the International Labour Organization (ILO) indicated that over 28 million individuals, spanning men, women, and children, are trapped in forced labor. The pressure to produce more for less leads to corner-cutting on safety standards and labor rights.

2. Social inequality:

Companies aiming to maximize profit margins often resort to paying low wages and offering unsafe employment conditions in regions with weaker labor laws. This exacerbates social inequalities, as workers, competing among themselves, remain trapped in poverty and dependent on low-paying jobs. Worker communities struggle economically, as they are unable to keep up with the relentless push for growth, and are often left behind, failing to share in broader economic gains, while a few wealthy individuals concentrate wealth and power even more.

At Qalara, our mission is to support and uplift local artisan communities by collaborating with enterprises that share our commitment to their welfare. We prioritize fair-trade practices to ensure that artisans are treated justly, with respect and dignity. Our partner-sellers adhere to strict guidelines that prevent exploitation, overworking, and unsafe working conditions, thereby fostering fair and equitable employment terms for artisans. Through these efforts, we strive to empower artisans and promote sustainable livelihoods, while also offering our customers ethically sourced and high-quality products.

3. Community well-being:

Overproduction in factories poses significant risks to workers’ physical as well as mental health. With increased pressure on workers to meet excessive production quotas, they work for long hours which elevates stress levels and causes fatigue. This can also lead to physical injuries from accidents or repetitive tasks. Moreover, the intensified use of toxic chemicals and substances in manufacturing processes exposes workers to health hazards such as respiratory issues, skin ailments, and long-term illnesses like cancer. Even global retailers like Zara and H&M have opted to terminate their manufacturing contracts and phase out operations in war-torn countries like Myanmar over claims of worker abuse and discrimination.

Finally, the excess waste generated from overproduction also contributes to pollution of the surrounding environment. This pollution poses a great risk to public health, exacerbating many dangerous ailments.

To tackle the underlying issues of overproduction, it’s vital for all manufacturers and businesses to work together. This involves advocating for sustainable consumption and production practices that prioritize the well-being of workers and safeguard the health of our planet for future generations.

Pragmatic approach to overproduction: For businesses

Embracing sustainable practices and challenging conventional methods may initially appear daunting. However, Qalara is here to guide you! Through the integration of innovative strategies and technological interventions, businesses can effectively minimize waste and significantly diminish their environmental footprint.

⬝ Better forecasting

Improved forecasting techniques stand as a cornerstone for businesses seeking to mitigate overproduction risks. Businesses can fine-tune their supply needs with precision using the following steps:

- Invest in retail technology: Implement advanced retail technology solutions that leverage historical data and predictive analytics to forecast future demand accurately.

- Utilize consumer insights: Gather and analyze consumer behavior data to understand trends and preferences, enabling more informed forecasting decisions.

- Continuous improvement: Regularly review and refine forecasting models based on performance feedback and emerging market trends to maintain accuracy over time.

This proactive approach not only optimizes inventory management but also fosters higher profit margins by minimizing wastage throughout the product lifecycle.

⬝ Tech integration

From design and planning to distribution, tech integration empowers businesses to optimize processes and respond swiftly to market fluctuations, thereby reducing the likelihood of overproduction. Integrating technology into operations can be achieved through the following steps:

- Assess current systems: Evaluate existing processes and technologies to identify areas for improvement and integration opportunities.

- Invest in automation: Implement automation solutions to streamline repetitive tasks and decision-making processes, freeing up time for strategic planning and analysis.

- Employee training: Provide comprehensive training programs to ensure staff members are proficient in using new technologies and systems effectively.

- Data security measures: Implement robust cybersecurity measures to protect sensitive data and ensure compliance with data privacy regulations.

Also read: The art of effectively using AI in retail and 5 game-changing shipping innovations of today and tomorrow

⬝ Shorter supply chains & stock aggregation

Streamlining supply chains and consolidating stock involves the following steps:

- Supplier evaluation: Assess and select suppliers based on criteria such as reliability, quality, and proximity, to reduce lead times and transportation costs.

- Inventory optimization: Implement inventory management software to track stock levels and demand patterns, enabling more efficient allocation and replenishment.

- Cross-channel coordination: Foster collaboration between online and offline sales channels to synchronize inventory levels and prevent stock imbalances.

⬝ Real-time planning

Embracing real-time planning and adopting shorter, more frequent buying cycles enables businesses to stay agile and responsive to evolving consumer trends. By aligning production with actual demand, this approach minimizes waste, optimizes cash flow, and reduces the need for markdowns, thus mitigating overproduction risks.

- Data-driven decision-making: Utilize real-time data analytics to monitor sales trends, inventory levels, and consumer behavior, enabling proactive decision-making.

- Collaborative tools: Invest in collaborative planning tools that facilitate communication and coordination between different departments involved in the planning process.

- Continuous monitoring and adjustment: Regularly monitor performance metrics and adjust production plans accordingly to optimize resource utilization and minimize waste.

⬝ Circular economy

The rise of circular economy concepts presents an opportunity for businesses to reimagine traditional operating models. By embracing these trends and integrating them into their product planning strategies, brands can foster sustainability while meeting consumer expectations for environmental stewardship.

- Product life cycle analysis: Conduct a thorough analysis of product life cycles to identify opportunities for improvement, including repair, refurbishment, and recycling. Furthermore, manufacturing methods, supply chain operations, and technologies should prioritize efficient resource utilization by optimizing water, energy, chemical, and material usage.

- Collaboration with partners: Businesses should uphold transparency by making their product specifications, chemical inputs, material sources, and production methods easily traceable. Collaborate with suppliers, retailers, and recycling organizations to implement closed-loop systems and promote circularity throughout the value chain.

- Consumer education: Educate consumers about the importance of circularity and encourage participation in recycling and product return programs.

- Innovation and design thinking: Foster a culture of innovation and design thinking within the organization. Products must be designed consciously so after maximum use, they can be reused, rebuilt, recycled, and, when it’s possible and safe, turned into compost.

Also read: How are big brands pledging to reduce waste and How to decode sustainability jargon

⬝ Made-to-order (MTO) & Made-to-measure (MTM)

A growing consensus among industry experts asserts that on-demand manufacturing is soon to become a vital aspect of the fashion industry’s future. MTO & MTM production models offer promising solutions to combat overproduction challenges, compared to traditional Ready to Wear (RTW). While MTO minimizes excess inventory by producing only what is already sold, MTM takes sustainability a step further by addressing sizing discrepancies and reducing waste through precise customization.

Here are some steps businesses can follow through to adopt these production models

- Customer engagement: Engage customers through surveys and feedback mechanisms to understand their preferences and sizing requirements.

- Digital measurement tools: Utilize digital measurement tools like 3D body scanning technology to capture accurate measurements for garments.

- Collaboration with suppliers: Partner with suppliers and manufacturers to develop flexible production processes capable of accommodating customization and short lead times.

Businesses should also communicate the benefits of MTO and MTM offerings to consumers, and emphasize sustainability, personalization, and reduced waste.

⬝ Success story

Kirby Best, CEO of OnPoint Manufacturing in Alabama, transitioned his knowledge from an on-demand book manufacturing unit to fashion. His company’s technology and facility enable fashion brands to swiftly and affordably bring on-demand products to market, all the while minimizing waste and upfront costs. Unlike traditional manufacturing, which often leads to excess inventory, on-demand production is efficient and responsive, producing items only upon booking a sale. Best contends that while there are challenges, such as initial investments and skill acquisition, the real obstacle lies in shifting industry mindsets toward embracing this transformative approach.

Change requires patience. When on-demand first came to the book publishing industry, the publishers initially resisted the model. Now they have adopted it broadly alongside (traditional) long-run offset printing. I believe the same thing will happen in the fashion industry.

Also read: Qalara’s order types: What works for you and check out Qalara’s MTO range here.

Global initiatives

In 2020, France passed a law to encourage businesses to be mindful of production waste and incorporate sustainability into their business models. The law also mandates that companies, including those in the fashion and cosmetics industries, will be prohibited from destroying unsold products.

Subsequently, Kering announced plans to cease the destruction of any unsold products globally starting in 2022. Following suit, Hermès stated in its annual report for 2022 that the company has halted the destruction of unsold items in France and will gradually extend this policy to its operations worldwide between 2025 and 2030.

Additionally, Kering has also embraced artificial intelligence to enhance sales forecasts and reduce unsold inventory at the end of each season. Reporting to The Business of Fashion, Kering revealed that it has achieved over a 20 percent increase in the accuracy of its inventory predictions, with ongoing improvements. In a parallel initiative, LVMH collaborated with Google in 2021, aiming for enhanced demand forecasting and optimized inventory management.

While brands strive to address the issue at the production stage, achieving precise synchronization between supply and demand remains an ongoing challenge. Consequently, luxury brands are also fostering partnerships with charities and educational institutions to donate and repurpose excess products, contributing to sustainable solutions.

Since the infamous ‘stock incinerating’ scandal in 2018, Burberry has changed its policies and taken active steps to promote sustainable practices and circular economy principles while nurturing creativity within the fashion industry. In 2020, they partnered with the British Fashion Council and donated surplus fabric annually to students studying fashion at the University of Brighton.

Student Leila Eskandary-Miles said about the project;

Having access to this fabric allowed me to experiment and be more ambitious with my ideas and execution, which in turn created an outcome I was extremely proud of. This initiative has inspired me to try and design with less waste, as well as to try and use deadstock fabrics and other pre-existing materials more.

Gucci also collaborated with a group of designers, brands, and artists for its Continuum initiative, integrating unused scrap materials into fresh, innovative products.

In 2023, the European Union proposed new laws (refer to pg. 40) to hold fast fashion accountable for aspects such as clothing quality, toxic chemical usage, and waste generation. If implemented, it is expected to compel fashion companies to produce higher-quality garments, reduce the use of harmful chemicals in their manufacturing processes, and minimize waste output.

India’s initiatives

A growing number of Indian brands are leading the charge in eco-conscious production, as they incorporate sustainability into their operations while championing a zero-waste ethos.

Qalara is one such platform! We are dedicated to providing a vast array of ethically sourced goods from South Asia and Southeast Asia at competitive wholesale rates, ensuring reliability and affordability. Additionally, we aim to empower producers and manufacturers by facilitating efficient access to global markets. Our focus lies in offering a diverse range of handmade, artisanal, eco-friendly, recycled, organic, fair trade and sustainable products, and more!

Here are some of our partners who are responsibly creating excellent quality products:

1. Embodying ‘one man’s trash is another man’s treasure’, this Delhi-based manufacturer crafts eco-friendly products from discarded denim, a material often wasted in factories and mills. With sustainability being at the core of their practices, they ensure that every bit of scrap is repurposed into beautiful and functional products. By upcycling, they not only create something unique but also contribute to reducing carbon emissions by extending the lifespan of textiles.

Check out more upcycled products here.

2. Combining ethical principles and market trends, this brand manufactures fashion accessories. The mission of this brand is to introduce eco-friendly alternatives to mass-manufactured products in the market. Their products are crafted from waste materials that are not commonly utilized in mainstream markets, like soiled cargo lashing belts, punctured bumper cars, and ex-army canvas. Moreover, these items are meticulously handcrafted by highly skilled artisans from North India.

Beyond offering sturdy and fashionable accessories, this label actively supports the ‘Make in India’ campaign, which provides vocational training and job opportunities in rural areas. Another outstanding aspect of this brand is that in addition to sustainability, their products are also quirky and timeless charms.

3. With a fusion of artisanal charm and steadfast commitment to sustainability, this manufacturer crafts elegant and functional pieces for contemporary living spaces. Their raw materials are eco-friendly and ethically sourced, ensuring every creation aligns with their eco-conscious ethos. Moreover, in a dedicated effort towards mindful production, they repurpose waste into stunning accessories.

Conclusion

The issue of overproduction looms large, significantly impacting the environmental, economic, and social health of our world. However, amidst these challenges, there lies an opportunity for transformation and renewal. As global initiatives and legislative measures gain momentum, there is hope on the horizon for a more sustainable and equitable world, where the legacy of overproduction is replaced by a legacy of resilience and responsibility. Through a pragmatic approach, businesses and consumers alike can become agents of change, each doing their part. Are you doing yours? We’d love to hear more in the comments!

~ Written by Yashvi

Leave a Reply